TEConcept IO-Link Products

In the case of IO-Link, TEConcept not only offers development services but also products. These products enable our customers to develop, certify and develop IO-Link based products.

It is our goal to support our customers with a comprehensive set of professional services and tools that allows them to develop their IO-Link products in a quick and cost-effective manner at a high level of quality.

We are active in the steering committee and various working groups of the IO-Link community and in particular in the IO-Link working group for quality and conformance testing. We are constantly identifying the need for new tools or services in order to improve our support to the IO-Link community. Recently an EMC test device and and IODD Editor have been developed. New tools are currently under development.

IO-Link Master Stack

Current sensors and actuators are equipped with small but powerful microprocessors that introduce advanced features like parameterization and diagnostics to these devices. However, those features are currently not visible to standardized project planning tools.

IO-Link, the new bi-directional, digital, point-to-point communication standard (IEC 61131-9) now offers a standardized mapping of advanced sensor and actuator features into the automation tool environment.

Our IO-Link master software stack allows automation system and machine tool providers an easy way to integrate state-of-the-art IO-Link technology into their products.

Master Stack Features

- Complies with latest IO-Link communication specification

- Multi-port support. The number of ports only limited by hardware resources.

- Cycle times:

- 0,4ms @ 230,4 kBaud

- 2,3ms @ 38,4kBaud

- 18ms@ 4,8kBaud

- System load max. 20MHz/Port (COM3-speed)

- Control and test API

- IO-Link SMI API support according v1.1.4 specification

- (advanced Fieldnet mapping support using our TSTL API)

Master Stack Description

The IO-Link master firmware library provides full access to all features and services defined in the IO-Link Communication Specification V1.1.x (latest v1.1.4) The stack supports all the important features such as ISDU, Interleaved Mode and diagnostics handling with event details. The standardized SMI API interface and our TSTL Layer supports easy integration to fieldbus/fieldnet mappings (like Profinet, EtherCAT, Ethernet/IP, etc...)

RTOS is NOT required for multiport applications. (but usage with RTOS is possible, already supports and tested with several RTOS)

Master Stack Delivery

- Development license including IO-Link Master stack source code

- Manufacturing license

- Documentation with installation manual and hardware adaptation description

- API user guide

- Demo application

- Compiler & linker example setups

- IO-Link configuration tool with IODD interpreter

Additional Services for Master Stack Customers

- Evaluation boards

- Software and hardware design and engineering support

- Conformance testing and test system rental (according to IO-Link Test Specification)

A demo Control Tool Software (CT) for the control of the stack via a connected PC simplifies access to the implemented functionality.

Processors supported by Master Stack:

- STMicroelectronics STM32 series (Cortex M0, Cortex M3, Cortex M4)

- Atmel ATSAM3S (Cortex M3)

- NXP LPC series (Cortex M0, Cortex M3, Cortex M4)

- Renesas RX series

IO-Link ASICs supported by Master Stack:

- STMicroelectronics L6360

- Elmos E891.10

- Linear Technology LTC2874

- Renesas CCE4510/or newer

- Maxim MAX14824/MAX14819

- ZMDI ZIOL2411

- Freescale CM3120

IDE / Compilers supported by Master Stack:

- KEIL-MDK

- IAR Toolchain

- Eclipse/GNU-GCC Toolchain / NXP LPCXpresso

Our flexible stack structure allows easy porting of our IO-Link Master stack to any microcontroller/ASIC to fulfill our business partners' requirements.

The supported MCUs or PHYs listed here are examples of existing portings. All the components listed are already verified/used with our stack. If you want to use another MCU or IO-Link PHY not listed here or you need a special hardware or FPGA-based design, please contact us.

The IO-Link V1.1.x Master Stack is offered as full source code buyout license. Please contact our sales department for licensing details.

IO-Link Device Stack

Current sensors and actuators are equipped with small but powerful microprocessors that introduce advanced features like parameterization and diagnostics to these devices. However, those features are currently not visible to standardized project planning tools.

IO-LinkTM, the bi-directional, digital, point-to-point communication standard (IEC 61131-9) now offers a standardized mapping of advanced sensor and actuator features into the automation tool environment.

Our IO-Link software stack opens sensor and actuator manufacturers a cost efficient and easy way to integrate state-of-the-art IO-Link technology into their products.

Device Stack specifications

- Compliant with latest IO-Link communication specification.

- Synchronous or asynchronous process data handling.

- ISDU support.

- Data storage.

- Parameter handler.

- Process synchronisation.

- System load ~ 50 % on 8-Bit processor @ 16 MHz.

- Porting to different µCs and IO-Link PHYs requires only an exchange of drivers.

- Matches to the current V1.1.4 IO-Link interface specification

- Allows synchronous and asynchronous process data access

- Support of data management

- Optimized for short response times

- System load ~ 50 % with a 8-Bit processor @ 14.7456 MHz.

- Modular stack design allows support and exchange of various IO-Link transceiver chips

Processors supported by Device Stack:

- STMicroelectronics STM32 (Cortex M0, Cortex M3, Cortex M4)

- STMicroelectronics STM8L/STM8S

- Renesas RL78

- Silicon Labs C8051F31x

- NXP LPC11xx (Cortex M0)

- Atmel ATSAM3S (Cortex M3)

- Atmel ATmega32/64/128

- Atmel ATtiny

- MSP430

- EFM32

ASICs supported by Device Stack :

- STMicroelectronics L6362

- Maxim MAX14820 / MAX14821 / MAX14827A / MAX14828

- Linear Technology LT3669/LT3669-2

- HMT microelectronic HMT7742

- Renesas CCE4502, ZIOL2401

- Texas Instruments SN65HVD10x, TIOL

Compilers/IDE supported by Device Stack :

- KEIL-MDK

- SiLabs IDE

- ST Visual Develop

- Eclipse/GCC/NXP LPCXpresso

- IAR

- Cosmic

Our flexible stack structure allows easy porting of our IO-Link Device stack to any microcontroller/ASIC to fulfill our business partners' requirements.

The supported MCUs or PHYs listed here are examples of existing portings. All the components listed are already verified/used with our stack. If you want to use another MCU or IO-Link PHY not listed here or you need a special hardware or FPGA-based design, please contact us.

Please contact our sales department for licensing details.

Device Stack sales information

- No limitation to single device ID.

- Driver for one processor architecture.

- Driver for selected IO-Link PHY-ASIC driver.

- IO-Link device stack API user guide.

- Installation manual and device driver API description.

- Demo application.

- Compiler and Linker example setups.

Additional Services for the Device Stack

- Evaluations boards.

- IO-Link device descriptor IODD design support.

- Software/Hardware design support.

- Conformance tests.

Firmware Update Profile

A new profile for updating the firmware of IO-Link devices is currently being specified. This profile will allow the user to update IO-Link devices in the field by using the standard IO-Link masters. The profile is fully compliant with the IO-Link Interface specification and does not need much more than a specific PC tool that handles the download process and communicates with the IO-Link master. The working draft of this new profile is already accessible to IO-Link members.

Device Bootloader for Firmware Update

In order to support the Firmware update a device must be equipped with a specific bootloader. On the master side, standard IO-Link masters can be used. Of course some software support that handles the update files is required.

Firmware Update Software Solutions

It is to be expected that in future many master manufacturers will provide tools that communicate with their masters to support IO-Link device firmware updates. Initially only a limited number of masters, in particular USB masters will be equipped with such a tool.

TEConcept is actively participating in this IO-Link working group and has already started to develop a "proof-of-concept" implementation of device that has the required bootloader and is also writing software tools that can interact with IO-Link masters that are equipped with the TEConcept Stack.

How to add the Firmware Update profile to your device?

After finalization of the firmware upload profile, TEConcept plans to offer firmware download bootloaders and IO-Link master solutions that support the new profile. This bootloader can be added to an existing IO-Link product. In addition to the integration of the new bootloader only a few modifications to an existing product are required to support the IO-link Firmware Update Profile.

USB based IO-Link 1-Port Master

Current sensors and actuators are equipped with small but powerful microprocessors that introduce advanced features like parameterization and diagnostics to these devices. However, those features are currently not visible to standardized project planning tools.

IO-LinkTM, the new bi-directional, digital, point-to-point communication standard (IEC 61131-9) now offers a standardized mapping of advanced sensor and actuator features into the automation tool environment.

The 1-Port USB Master is ideally suited for engineering purposes and small PC-based applications.

It uses the STMicroelectronics L6360 transceiver chip. A Windows based graphical user interface is included that reads IO-Link device descriptor files and offers an easy way to connect to all kinds of IO-Link devices.

1-Port USB Master Features

- Fully IO-Link V1.1.3 compliant

- All COM-speeds supported

- Data storage supported

- M12 IO-Link connector

- DIN rail mount

- PC-Tool included with

- IODD interpreter

- Process data visualization

- Event visualization

- Parameter R/W access

- IODD menu structure support

- IODD user role support

- Socket interface for process data

- Windows DLL option available for customized and software based access to the Master

Usage of the USB 1-Port Master

IO-Link 1-Port USB-C Master

Current sensors and actuators are equipped with small but powerful microprocessors that introduce advanced features like parameterization and diagnostics to these devices. However, those features are currently not visible to standardized project planning tools.

IO-LinkTM, the new bi-directional, digital, point-to-point communication standard (IEC 61131-9) now offers a standardized mapping of advanced sensor and actuator features into the automation tool environment.

The 1-Port USB-C Master is ideally suited for engineering purposes and small PC-based applications. It is now powered by the USB-C port. Devices with a current consumption of up to 500mA are supported. It supports the new SMI interface. The SMI-services are exchanged by the TEConcept serial transport layer protocol between PC and Master.

A Windows based graphical user interface is included that reads IO-Link device descriptor “IODD” files and offers an easy way to connect to all kinds of IO-Link devices. The GUI communicates with the Master via a TCP/IP that connects to an STCS server (see IO-Link Test Specification A3.3) that map SMI services in USB-telegrams.

1-Port USB-C Master Features

- Fully IO-Link V1.1.3 compliant

- All COM-speeds supported

- Data storage supported

- M12 IO-Link connector

- DIN rail mount

- PC-Tool included with

- IODD interpreter

- Process data visualization

- Event visualization

- Parameter R/W access

- IODD menu structure support

- IODD user role support

- Socket interface for process data

Usage of the USB-C 1-Port Master

USB based 4-Port Master

Current sensors and actuators are equipped with small but powerful microprocessors that introduce advanced features like parameterization and diagnostics to these devices. However, those features are currently not visible to standardized project planning tools.

IO-LinkTM, the new bi-directional, digital, point-to-point communication standard (IEC 61131-9) now offers a standardized mapping of advanced sensor and actuator features into the automation tool environment.

The 4-Port USB Master is ideally suited for engineering purposes and small PC-based applications.

It uses the STMicroelectronics L6360 transceiver chip. A Windows-based graphical user interface is included that reads IO-Link device descriptor files and offers an easy way to connect to all kinds of IO-Link devices.

4-Port USB Master Features:

- Fully compliant to IO-Link V1.1.3

- All COM-speeds supported

- Data storage supported

- M12 IO-Link connector

- DIN Rail Mount

- PC-Tool included with

- IODD Interpreter

- Process data visualization

- Event visualization

- Parameter R/W access

- IODD menu structure support

- IODD user role support

- Socket interface for process data

- 4-port support

- Windows DLL optionally available for customized and software based access to the Master

Usage of the USB 4-Port Master

- Simple evaluation of devices

- Engineering support

- Mini "PLC" that connects IO-Link sensors and actors.

One-Port Master Module

The IO-Link One-Port Master Module provides easy access to IO-Link devices without PLC.

The IO-Link master module contains an IO-Link compliant transceiver PHY together with a controller running a fully compliant IO-Link master stack.

The IO-Link master module can communicate with external hardware by SPI and/or UART interfaces.

Simple telegrams send over these interfaces allow control of the master

and provide easy access to process data and IO-Link configuration

diagnostic features.

Device configuration can be done offline by an integrated USB connector via a PC running a comfortable and self-explanatory IO-Link control tool.

The module can be plugged onto an existing board. For development purposes, a reference mother board is available.

One-Port Master Module Features

- Compliant to V1.1 IO-Link specification

- IO-Link transceiver with integrated protection

- L+ device power switchable

- SPI / UART interface for simple control of the Master

- USB interface for control of the Master using the TEConcept PC control tool

- Dimensions: 43mm x 33 mm

Mother Board features of the One-Port Master Module

- 24V power supply connector

- DB-9 serial connector

- Power supply for IO-Link master module

- M12-IO-Link Master connector

Typical Applications of the One-Port Master Module

Seamless integration of IO-Link devices into machine control or similar systems that work without classical PLCs.

Advantages of the One-Port Master Modul

- Development effort and cost reduced

- Time to Market shortened

- Cost advantages as no IO-Link master stack is required

Four-Port Master Module

The IO-Link Four-Port Master Module provides easy access to IO-Link devices without PLC.

The master module contains 4 fully tested IO-Link compliant transceiver PHYs together with a controller running a fully compliant IO-Link master stack.

The IO-Link master module can communicate with external hardware via SPI and/or UART interfaces.

Simple telegrams send over these serial interfaces allow communication

with the master and provide easy access to process data and IO-Link

diagnostic information of up to 4 connected devices.

Device configuration can be done offline by an integrated USB connector via a PC running a comfortable and self-explanatory IO-Link control tool.

The module can be plugged onto an existing board. For develop purposes a reference mother board is available.

(Optional customization of the 4-port master application software can be offered for low cost, stand alone mini PLC systems.

Four-Port Master Module Features:

- Fully compliant to V1.1 IO-Link interface specification

- IO-Link V1.1 compatible stack

- Integrated IO-Link transceiver and protection

- L+ device power switchable

- SPI interface for control and process data

- UART interface for control and process data

- USB interface for PC control

- Dimension: 59mm x 39mm

Motherboard features of the Four-Port Master Module:

- 24V power supply connector

- DB-9 serial connector

- Power supply for IO-Link master module

- M12-IO-Link Master connector

Typical Applications of the Four-Port Master Module

- Seamless integration of IO-Link devices into machine control or similar systems that work without classical PLCs.

- Stand-alone system that connects IO-Link devices and actors e.g. (Fillstate sensor -> Signal Tower)

Advantages of the Four-Port Master Module

- Development effort and cost reduced

- Time to Market shortened

- Cost advantages as no IO-Link master stack is required

Configurable-Observable Device

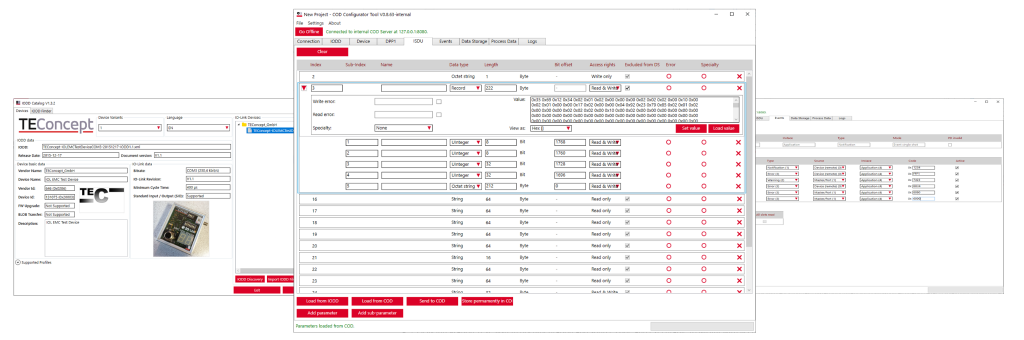

In the development of IO-Link Masters, there is often a strong need to test different edge cases. For example, how the IO-Link Master behaves at the largest data storage sizes, or how it reacts when the IO-Link Device does not respond or responds with a delay. The Configurable-Observable Device (COD) offers a wide range of possibilities to extend the regular protocol tests with custom tests for IO-Link Masters. In addition, COD can emulate any IO-Link Device based on its IODD.

The COD is an IO-Link Device that can be configured and parameterized via REST API. The actual hardware communicates with the PC via USB. The REST API is provided by a PC-side server application called COD Communication Server.

Configurable-Observable Device Features

- REST API for configuration and observation in automated test system

- PC application for easy configuration

- Emulate IO-Link Device by using its IODD

- Fully configurable dynamic ISDU parameter handling, with settable error generation for each index and sub-index

- Configurable DPP1 values (e.g. cycle time, process data, vendor and device ID, etc.)

- Event generation

- Process data mirroring, generation

- Observation of IO-Link communication and internal device variables (e.g., startup sequence, data storage flags)

- Error generation (e.g., emulation of a faulty device)

- Non-volatile memory to store configured parameters permanently

Usage of the Configurable-Observable Device

- 1 COD hardware

- PC configurator application

- COD Communication Server application